销售工程师 手机号:

邮箱:195152396

贵司名称?手机号?尊姓大名?项目名称?图纸和技术要求发我邮箱195152396

Heat ReCycle® 解决方案

通过创新的解决方案将短缺转化为优势。

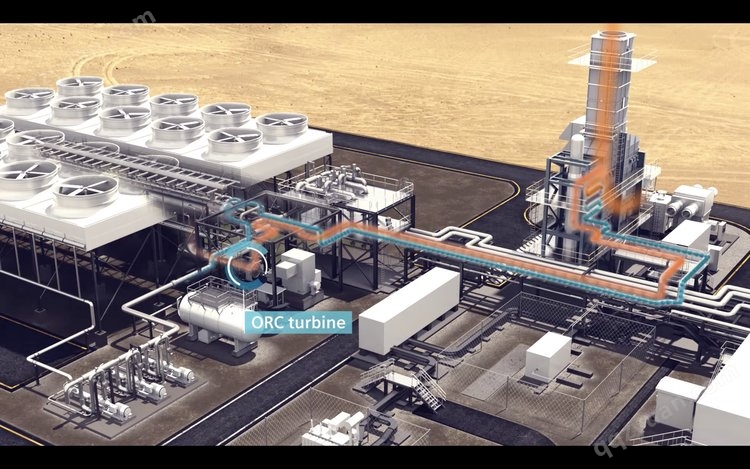

西门子能源燃气轮机与 Turboden 有机朗肯循环技术相结合,提供了的发电厂解决方案:Heat ReCycle®。

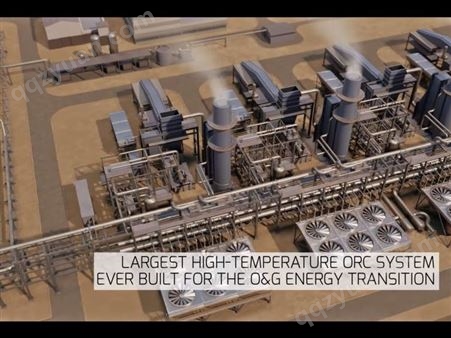

Heat ReCycle® 解决方案在世界上水资源稀缺的地区提供经济实惠的电力,提供无水解决方案并产生更低的排放。

与水/蒸汽循环相比,该发电厂专门设计用于降低 CAPEX 和 OPEX,同时保持高水平的效率。

Heat ReCycle® solution

Transforming a shortage into a strength by means of an innovative solution.

Siemens Energy Gas Turbines combined with Turboden Organic Rankine Cycle technology offers a unique power plant solution: Heat ReCycle®.

Heat ReCycle® solution provides affrodable electricity in regions of the world where water is a scarce resource, offering water-free solutions and producing lower emissions.

This power plant is designed specifically to reduce both CAPEX and OPEX compared to a w

联合循环

在联合循环中,Turboden ORC 装置可以安装在燃气轮机和往复式发动机的下游,通过回收废热来发电。在这两种情况下,联合循环的效率都大于 50%。在该应用中,Turboden 涡轮发电机的功率范围通常高达每个单轴 20 兆瓦的电力。

16

植物*

26.7

总兆瓦数

2008年

个工厂交付

*4 工厂正在建设中

Heat ReCycle® 解决方案

在联合循环中,Turboden ORC 装置可以安装在以下底部:

燃气轮机 ,额外功率高达 40 %

往复式发动机,额外功率高达 15%

在这两种情况下,联合循环的效率都大于 50%。

为什么选择有机朗肯循环技术?

高效利用高低品位和可变热源

运营成本低,无需水

添加可靠的电源,即使在偏远地区

提高发电厂的效率,降低对平准化电力成本 (LCOE) 的影响

基于特定现场功能的 ORC 热回收系统利用原动机的废气产生高达 30% ÷ 40% 的额外有用功率。ORC 系统遵循原动机的 运行模式,产生额外的电力(为电厂本身或外部用户),而不会对电厂运行产生任何影响。

典型解决方案

联合循环主要参考文献

兽人大小 地点 顾客 地位 笔记

0.5 兆瓦 Mezzana Bigli, 意大利 终端工业公司 自 2008 年开始运营 1x8 MWe MAN 柴油机余热发电

0.5 兆瓦 意大利波托格鲁阿罗 谷物码头 自 2012 年开始运营 利用 1x7 MWe Wärtsilä 柴油发动机的余热发电,直接交换

0.5 兆瓦 意大利卡塔尼亚 E&S 能源公司 离开 利用 2x1 MWe Jenbacher 燃气发动机的余热发电 + 3x0.8 MWe Jenbacher 燃气发动机 + 1x0.6 MWe Jenbacher 燃气发动机 - 垃圾填埋气

0.6 兆瓦 德国肯彭 市政厅肯彭 自 2012 年开始运营 利用燃气发动机的余热发电

0.7 兆瓦 德国森登 AGO AG 能源+植物 自 2012 年开始运营 利用 2x2 MWe Jenbacher 燃气发动机和工艺过程的废热发电

0.7 兆瓦 意大利佩斯卡拉 Alma CIS / Fater(宝洁集团) 自 2013 年开始运营 利用 1x8 MWe Wärtsilä 柴油发动机的余热发电,直接交换

0.7 兆瓦 比利时安特卫普 沼气技术公司 自 2019 年开始运营 利用废热发电 4 x 3.3 MWe Jenbacher 燃气发动机,带直接交换功能

1兆瓦 加拿大罗斯敦 跨气体 自 2011 年开始运营 利用气体压缩机站 3.5 兆瓦 Solar Centaur 40 燃气轮机的余热发电

1兆瓦 意大利奇瓦索 里恰雷利公司 自 2012 年开始运营 利用 1x17 MWe Wärtsilä 柴油发动机的余热发电

1兆瓦 乌兹别克斯坦安集延地区霍扎巴德 乌兹特拉加兹 建设中 利用气体压缩机站 3x15 兆瓦 GE 燃气轮机的余热发电

1.3 兆瓦 芬兰埃斯波 高铁 自 2011 年开始运营 利用 4x4 MWe MWM 燃气发动机的余热发电 - 垃圾填埋气

1.8 兆瓦 意大利皮斯蒂奇 里恰雷利公司 自 2010 年开始运营 利用 3x8 MWe Wärtsilä 柴油发动机的余热发电

2.3 兆瓦 土耳其奥达耶里 中东能源 自 2020 年开始运营 利用 12x1.4 MWe Jenbacher 燃气发动机的余热发电 - 垃圾填埋气

4兆瓦 意大利皮斯蒂奇斯卡洛 里恰雷利公司 自 2012 年开始运营 利用 2x17 MWe Wärtsilä 柴油发动机的余热发电

4.6 兆瓦 土耳其科穆尔库达 中东能源 建设中 利用 20x1.4 MWe Jenbacher 燃气发动机 + 4x1.2 MWe MWM 燃气发动机的余热发电 - 垃圾填埋气

5.5兆瓦 乌兹别克斯坦卡什卡达里亚地区舒尔坦 乌兹涅夫特加兹多比查 建设中 直接交换气体压缩机站 23 MW GE LM 2500 燃气轮机的余热发电

热回收®解决方案的涡轮增压器和西门子

2019 年,Turboden 和西门子推出了Heat ReCycle®解决方案,这是一种基于燃气轮机的发电厂,采用有机朗肯循环装置作为底部循环。与水/蒸汽循环相比,该发电厂专门设计用于降低 CAPEX 和 OPEX,同时保持相对较高的效率水平。

趋势正在创造市场挑战

人口的巨大增长,导致能源需求的增加。

城市化:乡村变成大城市,需要可靠的电力供应。

鉴于环境情况,这必须以我们考虑气候(变化)的方式来实现。

我们对今天和明天挑战的回应

Combined Cycles

In combined cycles, Turboden ORC units can be installed downstream of gas turbines and reciprocating engines, producing electricity by recovering waste heat. In both cases the combined cycle achieves an efficiency greater than 50%. The power of Turboden turbogenerators in this application generally ranges up to 20 MW electric per single shaft.

16

plants*

26.7

MWe total

2008

first plant delivered

*4 plants are under construction

Heat ReCycle® solution

In combined cycles, Turboden ORC units can be installed at the bottom of:

Gas turbines, with up to 40% of additional power

Reciprocating engines, with up to 15% of additional power

In both cases the combined cycle reaches an efficiency greater than 50%.

WHY ORGANIC RANKINE CYCLE TECHNOLOGY?

Efficient use of high-to-low grade and variable heat sources

Low operational costs and no water needed

Add a reliable source of power, even in remote locations

Improve power plants’ efficiency with a lower impact on Levelized Cost of Electricity (LCOE)

ORC-BASED COMBINED CYCLE

Designed upon specific site features, the ORC-based heat recovery system exploits the prime movers' exhausts to produce up to 30% ÷ 40% of additional useful power. The ORC system follows the prime movers' operation mode producing additional power (for the plant itself or for external users) without any impact on the power plant operation.

TYPICAL SOLUTIONS

COMBINED CYCLE MAIN REFERENCES

ORC SIZE LOCATION CUSTOMER STATUS NOTES

0.5 MWe Mezzana Bigli, Italy Termoindustriale S.p.A. In operation sin

0.5 MWe Portogruaro, Italy Cereal Docks In operation since 2012 Electric power production from waste heat from 1x7 MWe Wärtsilä diesel engine with direct exchange

0.5 MWe Catania, Italy E&S Energy S.p.A. off Electric power production from waste heat from 2x1 MWe Jenbacher gas engines + 3x0.8 MWe Jenbacher gas engines + 1x0.6 MWe Jenbacher gas engine - Landfill gas

0.6 MWe Kempen, Germany Stadtwerke Kempen In operation since 2012 Electric power production from waste heat from gas engines

0.7 MWe Senden, Germany AGO AG Energie+Anlagen In operation since 2012 Electric power production from waste heat from 2x2 MWe Jenbacher gas engines and from the process

0.7 MWe Pescara, Italy Alma CIS / Fater (P&G Group) In operation since 2013 Electric power production from waste heat from 1x8 MWe Wärtsilä diesel engine with direct exchange

0.7 MWe Antwerp, Belgium BiogasTech NV In operation since 2019 Electric power production from waste heat 4 x 3.3 MWe Jenbacher gas engines with direct excha

1 MWe Rosetown, Canada TransGas In operation since 2011 Electric power production from waste heat from a 3.5 MW Solar Centaur 40 gas turbine in a gas compressor station

1 MWe Chivasso, Italy Ricciarelli S.p.A In operation since 2012 Electric power production from waste heat from 1x17 MWe Wärtsilä diesel engine

1 MWe Hodzhaabad, Andijan Region, Uzbekistan Uztransgaz Under construction Electric power production from waste heat from 3x15 MW GE gas turbines in a gas compressor station

1.3 MWe Espoo, Finland HSY In operation since 2011 Electric power production from waste heat from 4x4 MWe MWM gas engines - Landfill gas

1.8 MWe Pisticci, Italy Ricciarelli S.p.A. In operation since 2010 Electric power production from waste heat from 3x8 MWe Wärtsilä diesel engines

2.3 MWe Odayeri, Turkey Ortadoğu Enerji In operation since 2020 Electric power production from waste heat from 12x1.4 MWe Jenbacher gas engines - Landfill gas

4 MWe Pisticci Scalo, Italy Ricciarelli S.p.A. In operation since 2012 Electric power production from waste heat from 2x17 MWe Wärtsilä diesel engines

4.6 MWe Komurcuoda, Turkey Ortadoğu Enerji Under construction Electric power production from waste heat from 20x1.4 MWe Jenbacher gas engines + 4x1.2 MWe MWM gas engines - Landfill gas

5.5 MWe Shurtan, Kashkadarya Region, Uzbekistan Uzneftegazdobycha Under construction Electric power production from waste heat from a 23 MW GE LM 2500 gas turbine i

环保、负担得起的电力热循环TM的可靠解决方案

我们的热循环解决方案由一个采用有机兰金循环(ORC)技术的燃气轮机发电厂组成。成熟的燃气轮机和ORC技术相结合,以有效回收废热,这是我们对当今世界各区域面临的市场挑战的回应。10亿人无法获得任何电力供应,另有10亿人缺乏可靠的电力供应;特别是那些位于偏远和偏远地区的电力供应。通过可靠的热循环发电厂解决方案,可以提供负担得起的电力,同时考虑环境和无水操作。

A reliable solution for environmentally sound, affordable electricity Heat ReCycle™

Our Heat ReCycle solution is comprised of a gas turbine power plant with Organic Rankine Cycle- (ORC) technology. The combination of proven gas turbine and ORC technology for efficient recovery of waste heat is our response to the market challenges which various regions of the world are facing today. One billion people do not have any access to electricity, and another billion have a lack of reliable power supply

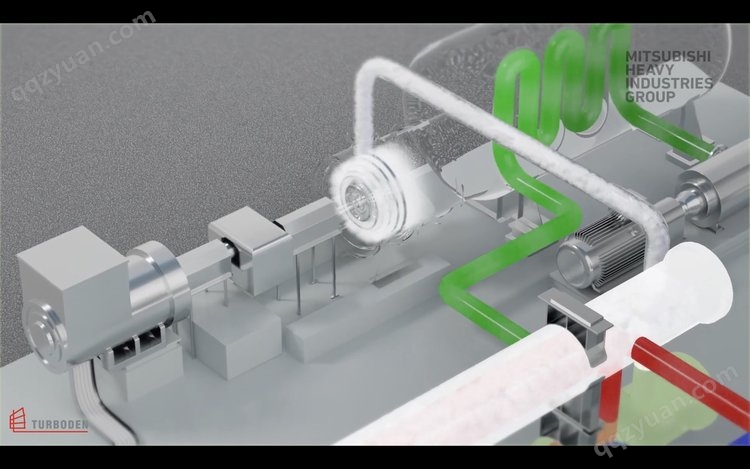

通过燃料的高效燃烧,燃气轮机发电并产生热废气。热废气中的热能通过废热回收单元(WHRU)回收,使用有机流体作为热交换介质。热有机液体用于为ORC涡轮机和发电机供电,以产生额外的电力。与水/蒸汽循环相比,这种组合循环的特点是简单,同时消除了对水的需求。

Electrifying rural and remote off-grid locations: Why LPG power plants are ideal

Combining gas turbines and an Organic Rankine Cycle, Heat ReCycle offers a compact solution for stand-alone energy requirements. Siemens Energy manager Wolfgang Klink takes us on a short walk in the woods to demonstrate why the use of LPG fuel makes this solution ideally suited for power generation in rural or remote off-grid areas.

Heat ReCycle is a gas turbine power plant with Organic Rankine Cycle (ORC) technology

Through the efficient combustion of fuel, the gas turbine generates electricity and produces hot exhaust gas. The thermal energy in the hot exhaust gas is recovered through a Waste Heat Recovery Unit (WHRU), using an organic fluid as the heat exchange medium. The hot organic fluid is used to power an ORC-turbine and generator to generate additional electricity. This combined cycle characterizes itself with sim

The Organic Rankine Cycle's principle is based on a turbogenerator working as a conventional steam turbine to transform thermal energy into mechanical energy and finally into electrical energy through an electrical generator. Instead of generating steam from water, the ORC system vaporizes an organic fluid, characterized by a molecular mass higher than that of water, which leads to a slower rotation of the turbine, lower pressures and no erosion of the metal parts and blades. The Heat ReCycle OR

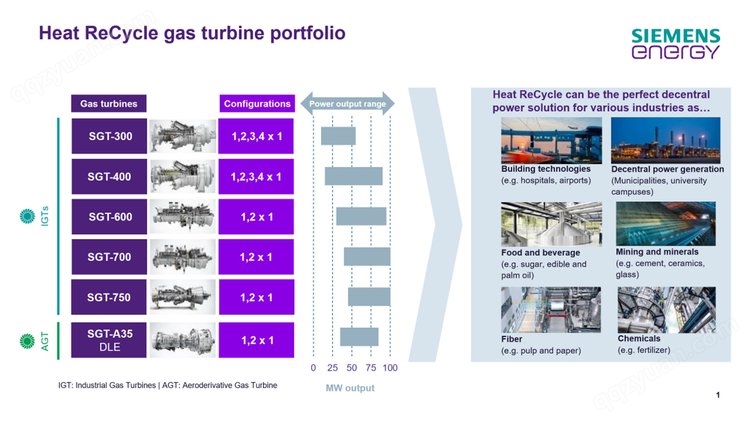

The Heat ReCycle range of power plants provides a wide choice of different industrial and aeroderivative gas turbines. The power plant can be customized for the required project-specific boundaries, such as power output and operating load regime. Heat ReCycle power plant configurations are possible from roughly 10 to almost 100 MWe capacity.

Heat ReCycle 3 x SGT-400 reference plant

The 3 x SGT-400 Heat ReCycle reference configuration is used as an example for explaining this new power plant in further detail. Having a three-on-one (3 gas turbines on 1 ORC turbine) configuration in the typical 50-MW capacity size range enables operational flexibility. Especially for remote locations, the 50-MW size range has traditionally been served by reciprocating engines or simple cycle gas turbines. Now, Heat ReCycle offers a cleaner and more ef

销售工程师 手机号:

邮箱:han

Sales Engineer

No.: +86 179

: hanguangshanghaitech

贵司名称?手机号?尊姓大名?项目名称?图纸和技术要求发我邮箱han

所有评论仅代表网友意见,与本站立场无关。